Safety Precautions

Always de-pressurize the system before maintenance. Wear PPE, including gloves and safety goggles. Ensure the trigger safety is engaged when not spraying. Follow all pressure relief procedures.

- Avoid spraying in explosive or hazardous environments.

- Keep the area well-ventilated to prevent fume buildup.

- Regularly inspect hoses and connections for damage.

1.1 Personal Protective Equipment (PPE)

Wearing proper PPE is essential to ensure safety while operating the Graco 395. Always use an air-fed respirator, protective suit, and chemical-resistant gloves when handling paints or coatings containing isocyanates. Safety goggles or face shields are required to protect against spray mist. Steel-toe boots are recommended to prevent foot injuries. Ensure all PPE meets regulatory standards. Full protective gear must be worn during spraying and when handling hazardous materials. Refer to the manual for specific PPE recommendations based on material usage. Failure to wear adequate PPE can result in serious health risks or injuries.

- Air-fed respirator for solvent-based or isocyanate-containing materials.

- Protective suit to prevent skin contact.

- Chemical-resistant gloves for handling paints.

- Safety goggles or face shields for eye protection.

1.2 Pressure Relief Procedures

To ensure safe operation, always follow pressure relief procedures. Switch the pump off and disconnect the power source before performing maintenance. Use the pressure relief valve to release any remaining pressure in the system. Ensure the pressure gauge reads zero to confirm depressurization. This prevents accidental spraying or equipment damage. Regularly check the pressure relief valve for proper function. Depressurize the system whenever changing tips or hoses. Always refer to the manual for specific instructions on pressure relief. Failure to relieve pressure can lead to serious injury or equipment malfunction. Follow these steps diligently to maintain a safe working environment.

- Turn off the pump and disconnect power.

- Activate the pressure relief valve.

- Verify zero pressure on the gauge.

- Perform maintenance only after depressurization.

Understanding the Graco 395 Equipment

The Graco 395 is a portable airless sprayer designed for architectural paints and coatings. It offers high-pressure performance, ensuring efficient and consistent application of materials.

2.1 Overview of the Graco 395 Sprayer

The Graco 395 is a portable airless sprayer designed for professional use, ideal for applying architectural paints and coatings. It features a compact design, making it easy to maneuver on job sites. The sprayer operates at a maximum working pressure of 3300 psi, ensuring high-efficiency painting with minimal downtime. Its robust construction and advanced technology provide consistent performance, catering to both small and large-scale projects. The unit is compatible with a variety of tips for different spray patterns and material viscosities, making it versatile for various applications. Regular maintenance and proper usage ensure optimal functionality and longevity of the equipment.

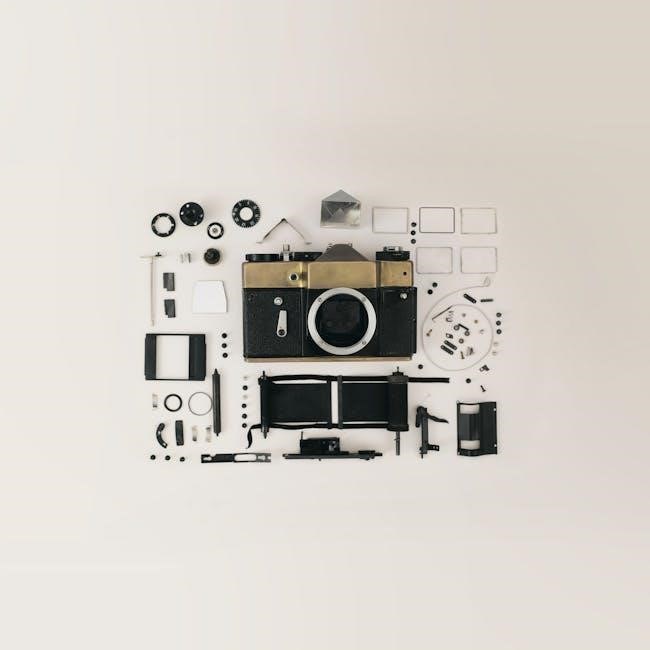

2.2 Key Components and Their Functions

The Graco 395 sprayer consists of essential components designed for efficient operation. The pump is the core, responsible for pressurizing paint to the desired pressure. The motor powers the pump, ensuring consistent flow. The spray gun features a trigger for control and tip guard for safety. The fluid hose connects the pump to the gun, withstanding high pressure. The tip or nozzle determines the spray pattern and width. The pressure gauge monitors system pressure, while the filter prevents debris from clogging the system. Each part works together to deliver a smooth, professional finish. Regular inspection of these components is crucial for optimal performance and longevity.

2.3 Compatibility with Paints and Coatings

The Graco 395 is compatible with a wide range of paints and coatings, including latex, oil-based, and epoxy. Ensure the material meets the sprayer’s pressure and flow rate specifications. Check the paint’s viscosity and recommended tip size for optimal atomization. Water-based paints typically require lower pressure, while thicker coatings may need higher settings. Always refer to the paint manufacturer’s data sheet for compatibility and application guidelines. Proper material selection ensures smooth operation and professional results. Testing with a small batch before full application is recommended to verify compatibility.

Operating the Sprayer

Prime the system thoroughly. Ensure the gun trigger safety operates. Use appropriate spray tips for material viscosity. Maintain consistent nozzle distance for even coverage. Monitor pressure and flow rates for optimal performance.

3.1 Preparing the Equipment for Use

Start by inspecting all components for damage or wear. Ensure the pump, hoses, and gun are free from obstructions. Check the filter and replace if necessary. Prime the system according to the manual to prevent airlocks. Attach the spray tip appropriate for the material being used. Test the equipment at low pressure to ensure proper function before full operation. Always refer to the Graco 395 manual for specific preparation steps to guarantee safe and efficient use. Proper preparation ensures optimal performance and minimizes the risk of equipment failure during spraying. Follow all safety guidelines outlined in the manual.

3.2 Priming the System

Priming the Graco 395 is essential to ensure proper material flow and prevent airlocks. Start by filling the material container with the recommended coating. Use a bucket or container to circulate the material through the pump. Turn the pump on and allow it to run for 2-3 minutes to prime the system thoroughly. Check for any leaks during this process. Once primed, test the spray gun at low pressure to ensure smooth operation. Always follow the manufacturer’s guidelines for priming to avoid damage to the equipment. Proper priming ensures efficient performance and minimizes downtime during spraying operations.

3.3 Best Practices for Spraying

For optimal results with the Graco 395, maintain a steady, consistent spraying motion. Keep the spray gun perpendicular to the surface and at a distance of 12-18 inches. Use overlapping passes to ensure even coverage. Avoid applying excessive material to prevent runs and drips. Work in well-ventilated areas and use a respirator with appropriate filters. Regularly clean the spray tip to maintain atomization quality. Adjust the pressure and flow rate according to the material being sprayed. Follow the manufacturer’s recommendations for tip sizes and operating pressures. Proper technique and setup will enhance finish quality and reduce material waste.

Maintenance and Troubleshooting

Regularly clean the spray tip and fluid system to prevent clogs. Lubricate moving parts to ensure smooth operation. Check for worn seals or damaged hoses.

- Replace faulty components promptly to avoid system failure.

- Consult the manual for troubleshooting common issues like low pressure or uneven spray patterns.

4.1 Cleaning and Lubrication

Regular cleaning and lubrication are essential for maintaining the Graco 395 sprayer’s performance. Always de-pressurize the system before cleaning to ensure safety. Use a mild solvent to remove paint residue from the gun, hoses, and tips. Lubricate moving parts, such as the trigger and piston, with a high-quality, non-stick lubricant. Avoid using excessive lubrication, as it may attract dust or debris. Clean the spray tip daily to prevent clogs and ensure a smooth spray pattern. For tough buildup, soak parts in a paint thinner solution overnight. Refer to the manual for specific lubrication points and cleaning procedures to maintain optimal functionality and extend equipment life. Proper maintenance prevents wear and tear, ensuring consistent results and reducing downtime. Regularly inspect and replace worn or damaged seals to avoid leaks and maintain pressure. By following these steps, you can keep your Graco 395 operating efficiently and effectively for years to come. Always prioritize thorough cleaning and lubrication after each use to uphold the sprayer’s performance and longevity. This routine will also help prevent common issues and ensure the system runs smoothly during your next project. Cleaning and lubrication are simple yet crucial steps that directly impact the sprayer’s reliability and output quality. They are essential for maintaining the equipment in good working condition and ensuring safety during operation. By incorporating these practices into your maintenance routine, you can enjoy consistent performance and extend the lifespan of your Graco 395 sprayer. Regular cleaning prevents the buildup of dried paint, which can obstruct the flow of material and lead to uneven spraying. Lubrication keeps the mechanical components running smoothly, reducing friction and wear. Together, these practices are vital for the overall health and efficiency of the sprayer. Always refer to the owner’s manual for detailed instructions and recommendations on cleaning and lubrication to ensure you are following the manufacturer’s guidelines. This will help you maintain the sprayer’s warranty and performance standards. Cleaning and lubrication are not just routine tasks; they are investments in the longevity and effectiveness of your equipment. By dedicating time to these processes, you can prevent costly repairs and ensure your Graco 395 continues to deliver professional-grade results. Remember, a well-maintained sprayer is a reliable tool that will support your projects for years to come. Always make cleaning and lubrication a priority after each use to uphold the quality and performance of your equipment. This attention to detail will pay off in the long run, ensuring your Graco 395 remains a trusted and essential tool in your workflow. Cleaning and lubrication are fundamental aspects of sprayer maintenance that should never be overlooked. They play a critical role in preventing malfunctions and ensuring the sprayer operates at its best. By staying consistent with these practices, you can protect your investment and achieve consistent, high-quality results in every project. Cleaning and lubrication are simple yet effective ways to maintain the performance and longevity of your Graco 395 sprayer. Always allocate time for these tasks to ensure your equipment continues to function optimally. Proper maintenance is key to extending the life of your sprayer and preventing unexpected issues; Cleaning and lubrication are essential steps that should be part of your regular routine. They help maintain the sprayer’s efficiency and prevent potential problems down the line. By prioritizing these tasks, you can keep your Graco 395 in excellent condition and ensure it continues to meet your needs for a long time. Cleaning and lubrication are vital for the smooth operation of the Graco 395 sprayer. Regular attention to these areas will prevent clogs, reduce wear, and extend the life of your equipment. Always clean and lubricate your sprayer after each use to maintain its performance and reliability. This consistent care will ensure your Graco 395 remains a dependable tool for all your painting projects. Cleaning and lubrication are crucial maintenance tasks that should be performed regularly to keep your Graco 395 sprayer functioning at its best. By following the recommended procedures, you can prevent issues and extend the lifespan of your equipment. Always remember that proper cleaning and lubrication are essential for maintaining the performance and longevity of your sprayer. They are simple steps that make a significant difference in the overall functionality and reliability of the Graco 395. Cleaning and lubrication are not just routine maintenance tasks; they are necessary for ensuring the sprayer’s optimal performance and preventing costly repairs. Always allocate time to clean and lubricate your Graco 395 after each use to protect your investment and maintain its effectiveness. This regular maintenance will ensure your sprayer continues to deliver professional-grade results for years to come. Cleaning and lubrication are essential for the proper functioning of the Graco 395 sprayer. Regular maintenance prevents clogs, reduces wear, and ensures smooth operation. Always prioritize cleaning and lubrication after each use to uphold the performance and longevity of your equipment. This consistent care will ensure your sprayer remains a reliable and efficient tool for all your projects. Cleaning and lubrication are vital for maintaining the Graco 395 sprayer’s performance and extending its lifespan. Regular attention to these areas prevents issues and ensures optimal functionality. Always clean and lubricate your sprayer after use to protect your investment and achieve consistent results. Proper maintenance is key to keeping your equipment in excellent condition and ensuring it continues to meet your needs effectively. Cleaning and lubrication are simple yet crucial tasks that should be part of your regular maintenance routine for the Graco 395 sprayer. By dedicating time to these processes, you can prevent malfunctions, reduce wear, and extend the life of your equipment. Always remember that consistent cleaning and lubrication are essential for maintaining the sprayer’s performance and reliability. They are investments in the longevity and efficiency of your tool. Cleaning and lubrication are not just routine tasks; they are necessary for ensuring the Graco 395 sprayer operates at its best. Regular maintenance prevents clogs, reduces friction, and extends the life of your equipment. Always prioritize cleaning and lubrication after each use to uphold the quality and performance of your sprayer. This attention to detail will ensure your Graco 395 remains a trusted and essential tool for all your painting projects. By maintaining a consistent cleaning and lubrication routine, you can protect your investment and achieve professional-grade results consistently. Cleaning and lubrication are fundamental aspects of sprayer maintenance that should never be overlooked. They play a critical role in preventing malfunctions and ensuring the sprayer operates efficiently. Regular cleaning removes paint residue and debris, while lubrication keeps moving parts running smoothly. Always refer to the owner’s manual for specific instructions on cleaning and lubricating your Graco 395 sprayer. This will help you follow the manufacturer’s recommendations and ensure your equipment is well-maintained. Cleaning and lubrication are essential steps that should be performed regularly to keep your sprayer in optimal condition. By staying consistent with these practices, you can prevent issues, reduce wear, and extend the lifespan of your Graco 395. Always allocate time for cleaning and lubrication after each use to protect your investment and maintain the sprayer’s performance. Proper maintenance is key to ensuring your equipment continues to function effectively and deliver the results you need. Cleaning and lubrication are vital for the smooth operation and longevity of the Graco 395 sprayer. Regular attention to these areas will prevent clogs, reduce friction, and ensure optimal performance. Always prioritize cleaning and lubrication after each use to uphold the quality and reliability of your equipment. This consistent care will ensure your sprayer remains a dependable tool for all your painting projects. By incorporating these maintenance tasks into your routine, you can protect your investment and achieve consistent, professional-grade results. Cleaning and lubrication are not just routine tasks; they are necessary for ensuring the Graco 395 sprayer operates at its best. Regular maintenance prevents issues, reduces wear, and extends the life of your equipment. Always clean and lubricate your sprayer after each use to maintain its performance and longevity. This attention to detail will ensure your Graco 395 continues to be a reliable and efficient tool for years to come. Cleaning and lubrication are essential for maintaining the performance and longevity of the Graco 395 sprayer. By following the recommended procedures, you can prevent malfunctions, reduce wear, and ensure optimal functionality. Always prioritize cleaning and lubrication after each use to protect your investment and uphold the quality of your equipment. Regular maintenance is key to extending the life of your sprayer and ensuring it continues to meet your needs effectively. Cleaning and lubrication are simple yet crucial tasks that should be part of your regular maintenance routine for the Graco 395 sprayer. By dedicating time to these processes, you can prevent issues, reduce friction, and extend the lifespan of your equipment. Always remember that consistent cleaning and lubrication are essential for maintaining the sprayer’s performance and reliability. They are investments in the longevity and efficiency of your tool. Cleaning and lubrication are not just routine tasks; they are necessary for ensuring the Graco 395 sprayer operates at its best. Regular maintenance prevents clogs, reduces wear, and extends the life of your equipment. Always prioritize cleaning and lubrication after each use to uphold the quality and performance of your sprayer. This attention to detail will ensure your Graco 395 remains a trusted and essential tool for all your painting projects. By maintaining a consistent cleaning and lubrication routine, you can protect your investment and achieve professional-grade results consistently. Cleaning and lubrication are fundamental aspects of sprayer maintenance that should never be overlooked. They play a critical role in preventing malfunctions and ensuring the sprayer operates efficiently. Regular cleaning removes paint residue and debris, while lubrication keeps moving parts running smoothly. Always refer to the owner’s manual for specific instructions on cleaning and lubricating your Graco 395 sprayer. This will help you follow the manufacturer’s recommendations and ensure your equipment is well-maintained. Cleaning and lubrication are essential steps that should be performed regularly to keep your sprayer in optimal condition. By staying consistent with these practices, you can prevent

Warranty and Support

4.2 Common Issues and Solutions

Common issues with the Graco 395 may include clogged spray tips, pressure loss, or motor overheating. For clogs, clean the tip with a solvent or replace it if damaged. Pressure loss can be resolved by checking for worn seals or loose connections. Overheating may occur due to excessive use; allow the motor to cool down before resuming. Always refer to the manual for troubleshooting specific problems. Regular maintenance, such as cleaning and lubricating, can prevent many of these issues. If problems persist, contact Graco customer support for assistance. Proper care and timely solutions ensure optimal performance and extend equipment life. Addressing issues promptly helps maintain reliability and efficiency.